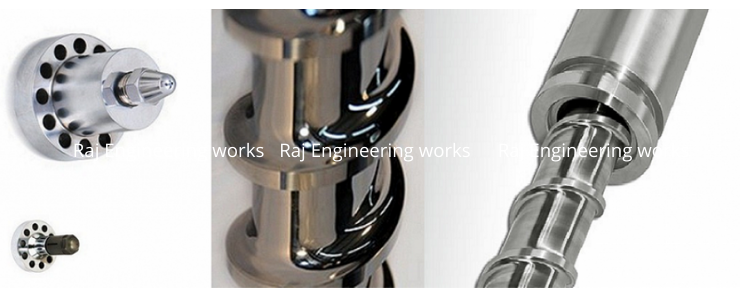

Injection Molding Screw Barrels

Inquiry NowWe make Injection Moulding Screw Barrel for some of the largest companies in India. To see our customer list see pictures at the end of this page. Injection Moulding screw barrels are easiest type of screw barrels as they are simple and have less flights compared to body ratio.

One important thing to be noted while procuring injection molding screw barrel is you must have drawing of your screw, otherwise a manufacturer will charge much more than the original cost of that shaft. So whenever you buy screw, ask your supplier to provide drawing and check your screw according to drawing, which is not a rocket science.

If you have a drawing you need not to disclose your machine/model number, what polymer you process in what composition.

You can keep your processing details confidential, and send drawing in mail to all manufacturer, ask them to submit quote according to your drawing.

Injection molding feed screws can be economical if you have drawing.

Another important thing is to know the details of your required bimetallic coating or Carbide coating, because coatings range from 0.0 % (W) Tungsten to 90% (W) Tungsten, so the price you are paying is for material used in coating and the method used to apply coating.

To learn more technical details and get an estimate for your screw barrel call us at +91-8128381431.

Raj Engineering Works (REW) is Ahmedabad based OEM (original equipment manufacturer) which means we make feed screw barrel for different machine manufacturers/ assemblers/suppliers without asking them the model number/output/applicable polymers because to make any screw we do not need such information.

The manufacturing cost at OEM is very low compared to Supplier/Machine manufacturers. (Read above)

At Raj Engineering Works we have advanced technology to make screws at any precision level, we can make a screw within 3 hours (Thread Milling), and then for Gas nitriding and grinding, polishing, etc we need 10-15 days, so overall you can get a screw as fast as 10 to 12 days.

We supply screw barrels in bulk to other screw barrel manufacturers/suppliers located in Ahmedabad, Delhi, and Mumbai. Disclosing the names of our 'bulk' customers is against the statutory agreements and business policies. However, you visit our factory, any day, between 8 am to 8 pm.

Screw diameter 22 mm to 250 mm

Screw up to 5200 mm in one piece and 9000 mm in two pieces.

Barrel OD up to 350mm.

Materials:

EN41B Nitriding steel (Musco) (default), German Imported 41CrMoAl7 Equivalent, China's 38CrMoAlA also available on special request.

Hardfacing alloy - Stellite and Colmonoy

Hardfacing Superalloys - Inconel , Hastelloy

Gas nitriding: Thickness from 0.5 to 0.7 mm, hardness ~ 60-75 HRC ~ 1000 HV.

Plasma Nitriding on special request is also available.

Hard chrome plating as the default process in all screws.

Bimetallic treatment with HSS M type or Tool steel D2.

Ultimate solution for abrasive and wear resistance WCNi Carbide Matrix composite with 88% Tungsten

Method: HVOF, HVAF, TPA, Sprayweld, Sintering

Production time: Within 2-4 weeks depending on the complexity o