Nitrided Screw Barrel

Inquiry Now100% Adhesive wear resistant nitrided screw barrel

Our Screw Barrel are made of MSSSPL EN41B (Musco) Nitrite Alloy Steel, or 41CrMoAl7 equivalent Germany or China Imported.

38CrMoAlA, 33CrMoAl4 and other nitriding steel also available as per request.

We use world's top grade Nitriding Alloy Steel as base materials in all Plastics industry standard feed screw & barrels.

Liquid and Plasma Nitriding option is also available, need to mention in P.O.

Production range: From 32 to 300 mm x up to length 6000 mm (in one piece).

Parameters of nitrided layer: Thickness from 0.5 to 0.7 mm, hardness ~ 60-70 HRC ~ 1000 HV.

Production time:Within 4 weeks depending on the complexity of the part

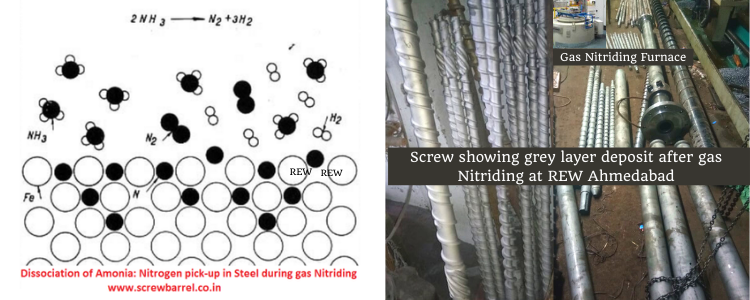

Nitriding process: The principle of nitriding process is based on penetration of atomic nitrogen into the peripheral steel layer with the temperature of 550 C and it causes increasing the peripheral toughness by formation of nitrites and by depositing the nitrided atom in areas between grids which causes grid tension. The peripheral zone consisting of a diffuse zone and an interface layer has high toughness, good wear resistance, increased fatigue limit and increased corrosion resistance.

| Steel | Surface Hardness after gas nitriding (HRC) | Depth (mm) |

| Cast Iron | File hard | 0.0508 -0.254 |

| En19 equivalent 42CrMo4, 25CrMo4, 34CrMo4 | 52-58 | 0.2032 -0.6096 |

| 4340, En41b, 41CrMoAl7, 38CrMoAlA | 60-65 | 0.2032 - 0.7023 |

| 132M | 67-71 | 0.2032 - 0.508 |

| P20 | 57-62 | 0.2032 - 0.508 |

| A-2, D-2 | 65-70 | 0.127 - 0.254 |

| H13, S-7 | 67-71 | 0.1016 -0.3048 |

| M-2, M-4, M-42 | 69-72 | 0.0127 -0.0508 |

| 304, 316, SST | 62-66 | 0.0 |

Read about Bimetallic Screw Barrel