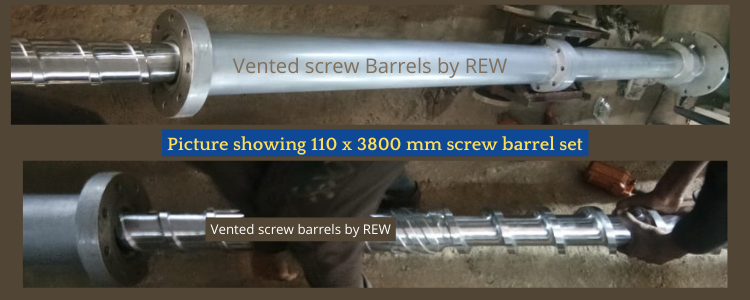

Vented Screw Barrel

Inquiry NowWhat is a vented screw ?

Vented screws are essentially two screws in one.

A vented or two-stage screw is essentially two screws on the same shaft. The first works as a conventional screw by feeding, melting, and conveying the polymer forward. The second screw does the same, except it is melt-fed by the first screw. The first screw operates with no head pressure, while the second has to overcome any head pressure from the die and other downstream components. In order to keep the vent section of the screw from filling and developing vent flow, the second screw must have more output capacity than the first screw. Proper design of a two-stage screw requires knowledge of the polymer viscosity, the output capacity of both stages, and the head pressure. Simply using a ratio in channel depths between the first and second metering sections is risky.

Proper venting with no leakage or vent flow does not depend solely on the design of the screw. The barrel vent opening has to be fitted with a contoured plug called a diverter. The diverter deflects polymer away from the opening or else it will quickly become filled with melt. Its design is more of an art than a science but there are many variations that work, all using the same principles.

How does a vented screw function?

First, it reduces the melt pressure to atmospheric, so there is no tendency for the polymer to be pumped out the vent opening. That is accomplished by increasing the channel volume so that the output of the extruder only partially fills the flights under the vent.

About Raj Engineering Works Vented Screw Barrel

Screw diameter 75 mm to 250 mm

Screw length up to 5000 mm in one piece and 9000 mm in Two piece.

Barrel OD upto 350mm.

Materials:

EN41B Nitriding steel (Musco) (default), German Imported 41CrMoAl7 Equivalent, China's 38CrMoAlA on special request.

Hardfacing alloy Stellite and Colmonoy

Hardfacing Superalloys - Inconel, Hastelloy, Tungsten and Tungsten-Boron-chromium based composites.

Gas nitriding: Thickness from 0.5 to 0.7 mm, hardness ~ 60-75 HRC ~ 1000 HV.

Plasma Nitriding on special request also available.

Hardchrome plating as default process in all screw.

Bimetallic treatment with HSS M type or Tool steel D2.

Coatings:

Ultimate solution for abrasive and wear resistance WCNi Carbide Matrix composite with 88% Tungsten metal coating by HVOF or TPA or Spraywelding depending on application.

Production time: Within 2-4 weeks depending on the complexity of the part.

When you focus on one thing for a long time, you Master it.

Go to previous page if you want to know more about our vented screw barrel.

Since last 20 years we have focused only on screw-barrel-engineering, thus it is our product-quality & customer-relation which speak louder than others in market.

We are largest and reputed manufacturer and supplier of vented screw barrel in Ahmedabad.

Our screw are manufactured using advanced technology and machine which provide various features such as strong ability, durability, exact fitting, easy to use and remove etc. our products are specially designed to meet customers specific need and requirements.

Read more on our Vented Screw

You are in products section page number 13.

© 2021 Raj Engineering Works

This website is under artificial intelligence supervision and copying data, keywords from this site is a punishable offence.